Shift Transfer Model, Communication between plant teams is critical to ensuring facility safety. During the transfer of responsibility from one team member to another, a crucial element may go unnoticed. Continuity in the handover procedure depends on effective communication. The safety of the public is at stake if this communication is compromised in any way. At worst, this could have resulted in a fatal accident.

Transfer of responsibility to a new shift:

Any ongoing process requires frequent shift changes. On the other hand, plants can work non-stop, while humans must rest. As the shift handover model cannot be automated and depends on human behavior, it should be considered a high risk activity. Continuity and official transfer of duties and responsibilities are the main objectives of the transfer procedure.

Change-to-change activities

A shift schedule is usually established in advance for those who must adhere to a certain schedule. Changeover times for shifts are predetermined. Critical repairs and offloading of bulk raw material occur on their real-world schedules. Two or more shift transfer models may be required to complete these tasks, involving multiple groups. A major repair, for example, can take days, weeks, or even months to complete.

Change the delivery procedure

The shift handover model follows a defined method to avoid confusion and ensure accuracy. Each company will design its procedure based on the specifics of its business operations. While some companies adhere to a highly rigid and well-defined strategy, we’ve seen others rely solely on individuals to successfully communicate during the transition process.

The shift transfer model has several risks.

Since shifts last 8 or 12 hours, there are 730 or 1,095 chances of miscommunication leading to safety issues every year. Focusing on ensuring the change process is well defined and managed properly is an important part of improving plant safety. Several studies on the shift change have been carried out to better understand the procedures. The HSE studied several instances involving planned maintenance work and revealed that risks related to the shift transfer model were a contributing factor to accidents and fatalities.

over one turn deliver model change, planned maintenance work continued in some cases. The need for thorough planning and communication for this type of work cannot be overstated. operator support [logs] they were not intended to capture important information reliably and unambiguously. There was a notable absence of guidelines for performing a successful shift change. There was a notable lack of accuracy and reliability in transferring written information between shifts. For example, there was no mention of a temporary replacement of the security system.

Shift change and work permit

The work permit is typically used in industrial settings to ensure that all workers involved in hazardous and non-routine factory work are in contact with each other. These licenses must be transferred at the end of the shift. There are two ways to do this: the previous shift’s permission expires and the new one gets a new one to allow work to continue. The permit document itself passes the responsibility of outgoing employees to incoming employees via a shift change method.

Using the second way is more efficient, but there is a chance that something crucial has changed and those responsible are not sufficiently questioned in the transition. It’s hard to say which way is better, and procedures also vary by industry.

In contrast to chemical manufacturing, the nuclear business follows a more systematic handoff process. Furthermore, an intriguing disconnect was discovered in the HSE study [1]. During a survey of factory personnel, most installers and superintendents were in favor of issuing a new permit at the time of transition, while most managers supported the idea of continuing to use the same permit. There seems to be room for uncertainty due to this lack of alignment.

- It’s a related post.

- Using your security data to its fullest potential

- Using your security data to its fullest potential

An advantage of a digital security system is its ability to provide greater security insights through the use of collected data. Only a small percentage of companies take the step of analyzing their security data, let alone creating action plans based on it.

What are the best practices for shift transfer?

The following design ideas should guide the creation of an efficient shift change procedure: An electronic logbook is preferable to a paper log as it is straightforward, secure and organized; in addition to the “what”, inter-turn information should also explain why. Between shifts, information must be exchanged between those who know the process and the task being performed. Everyone affected by the situation must have access to relevant information such as monitors around the factory, mobile devices and so on.

How does IntelliPERMIT facilitate and authorize shift changes?

As a result, IntelliPERMIT is designed to maximize operational efficiency and minimize operational risk. Since its inception, the system has expanded far beyond a simple computerized permission-to-work system to support the multiple functions performed at the plant, including shift change. When it comes to supporting the transfer and work permit processes, IntelliPERMIT does a number of things, including:

The permission has new signers.

On shift change, IntelliPERMIT adds the signatures of the outgoing and incoming personnel to the signatures of the responsible persons on the license.

Taking into account your company’s policies:

As a result, the system can work with your current workflows.

Create a new permission as soon as possible, if necessary.

At handover, IntelliPERMIT makes it easy to generate a new license in minutes. The old permission is terminated as usual and a new one is started, which inherits some of the information from the old one. A new permission can be created, information reviewed and new signers secured, which aids in communication between shifts.

Maintain insulation integrity:

You can link multiple permissions with dependencies to isolations. If a new ticket is generated, the integrity of the isolation can be maintained even during the handover. System users can view permissions associated with isolations through a hierarchical view, which can accommodate extremely complicated scenarios. Integrate the logbook for the transfer of shifts with the inclusion of permits.

Shift transfer log management is an optional feature of the IntelliPERMIT system. It is possible to link these logs to other operational procedures, filling them with templates pre-established by the company.

Make sure work permit reviews are part of regular operations meetings.

During production meetings, IntelliPERMIT has an optional module that organizes the schedule and tracks decisions made. Meetings of this type often occur at the end of a turn. As a result of this “meeting minutes” module, groups can move through a pre-determined schedule more quickly because all essential real-time data is displayed on a single screen. Meeting minutes and tasks are recorded automatically.

People on shifts must be monitored.

The IntelliPERMIT system has a shift scheduling module that makes it easy for companies to keep track of their various production and maintenance schedules and teams. There is a direct link between this data and other essential operational support systems.

Work orders related to plant maintenance can be found here.

It is also possible to integrate IntelliPERMIT into the computerized maintenance management system, allowing for the coordination of shift changes.

A single operations database such as IntelliPERMIT makes it easy to integrate data from multiple processes into a single database. After analyzing this data, several important insights can be gained.

These processes must work together to promote efficiency and maintain the safe and efficient operation of a business. When it comes to shift changes, efficient communication is crucial to reducing the likelihood of safety issues.

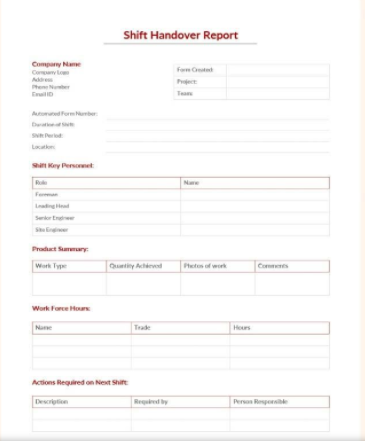

Handing over a shift handover model is critical to conveying any difficulties or duties that arose while you were on duty to the new team. There’s a good chance you already have a template in place. It is the best choice for individuals who have just started a shift or need a shift transfer template format. Do you have a process for transferring responsibility to the next support team? It all depends on the company and the group. Among the many possibilities that come to mind, here are some examples.

Email transfer is one of the oldest and most widely used techniques for transmitting information. Communication about difficulties in the production environment or work you were involved in while in your time zone is best communicated via email. An email has its drawbacks in explaining complex topics, which can be done much faster and easier over the phone.

make a call

You’ll love it if you’re more talkative. When your shift is over, dial your next team’s phone number. If the next turn takes place in the same building or location, this may not apply. Remember that while this method is simple, there is no record of what you gave up. Phone calls will be more expensive than email if you are transferring to another nation.

Chat

- Emails and phone conversations are my preferred methods of communication.

- Which one are you currently using?

You may not need a standard template if you communicate via chat or phone. If you’re going to use email, it’s a good idea to create a template that everyone on your team can use. Using a consistent template will help ensure that all team members are on the same page.

Also read: 5 ways to overcome logistical communication challenges.